Thread inserts: a technical solution for reinforcing your industrial assemblies

In demanding industrial environments, the reliability and durability of screw connections are essential criteria for guaranteeing equipment performance and plant safety. Whether in the aerospace, automotive, energy or rail industries, the materials used for structures and components often have to be both light and strong. However, certain materials such as aluminum, magnesium or composites are particularly sensitive to mechanical stress and repeated loads, increasing the risk of thread wear.

Thread inserts are an effective technical solution for improving the mechanical strength of screwed joints. They are used both to reinforce threads in soft materials and to repair damaged taps, thus reducing the risk of breakage or pull-out.

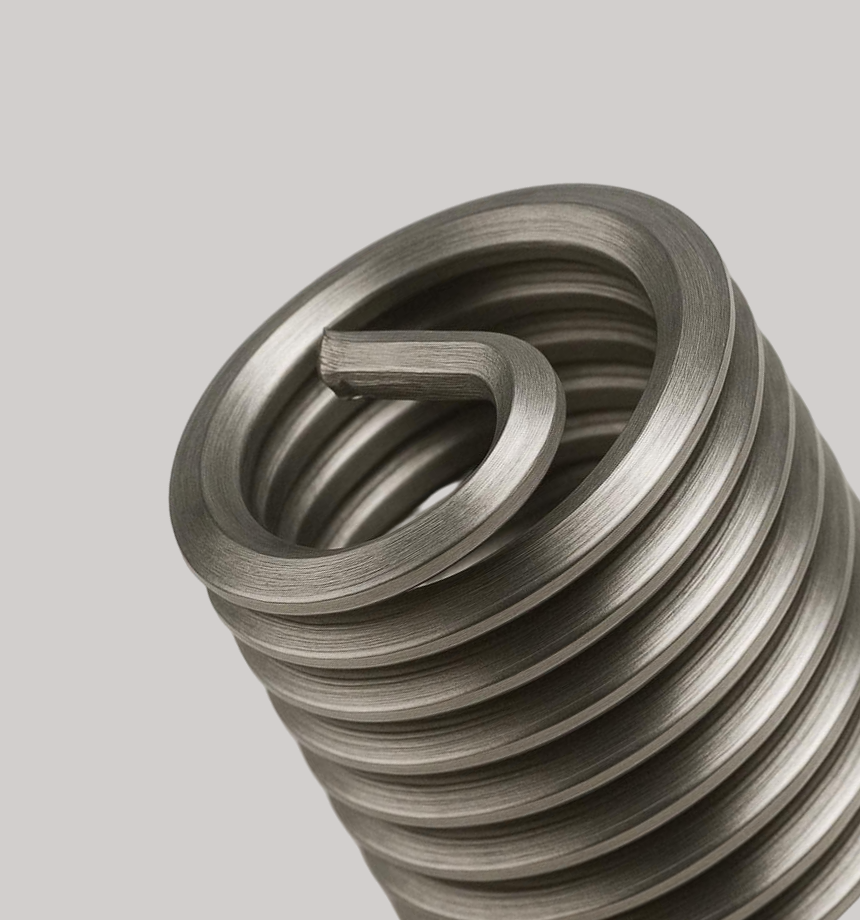

What is a net insert?

The net insertalso known as insert threadis a spiral-shaped metal insert designed for installation in a pre-machined thread. Made from high-performance stainless steel, it is designed to withstand the most demanding mechanical stresses.

The insert creates a reinforced internal thread that distributes loads evenly over the entire thread, thus limiting the stress concentration effect. This process not only extends the service life of screwed assemblies, but also guarantees greater reliability, even under extreme operating conditions.

The characteristics of a mesh insert

Why integrate a thread insert into an industrial assembly?

The mechanical stresses exerted on screw connections can lead to premature wear of the threads, particularly in low-hardness materials. The net insert is a proven technical solution that offers several major benefits:

Thread reinforcement in low-hardness materials

Thread inserts are used to secure tapped holes in materials sensitive to mechanical stress, such as aluminum or light alloys. They increase resistance to repeated loads and improve vibration resistance, guaranteeing more reliable fastening.

Reduced maintenance costs and production downtime

When a thread is damaged, replacing it can lead to high costs and equipment downtime. By installing a thread insert, a thread can be restored without having to replace the entire part, optimizing maintenance and reducing operating costs.

Longer service life for screw connections

By distributing mechanical loads more evenly, thread inserts reduce the effects of material fatigue and prevent premature fastener failure.

Compliance with industry standards

Thread inserts meet the stringent requirements of high-tech industries, guaranteeing performance in line with current standards.

Improved thermal and mechanical resistance

Thanks to their stainless steel design, thread inserts are resistant to temperature variations and high mechanical stress. They are particularly suitable for applications subject to extreme conditions.

Industrial applications of thread inserts

Thread inserts are used in a wide range of industrial applications requiring reliable, durable screw connections.

Aerospace

In the aerospace industry, the use of lightweight materials is essential to optimize aircraft energy consumption. However, these materials are often more brittle than steel, requiring thread reinforcement to avoid any risk of breakage. This is why thread inserts are widely used in structures such as fairings.

Automotive & Transportation

In the automotive sector, mechanical components must be able to withstand extreme conditions, including wide temperature variations and high vibratory loads. Thread inserts ensure reliable fastening.

Rail and infrastructure

Railway infrastructures and associated mechanical equipment are subject to intense mechanical stresses due to vibrations and traction forces. Thread inserts ensure greater stability of fasteners and limit the risk of premature wear.

Precision industry and electronics

The electronics and micromechanics sectors require precise, reliable fastening solutions. Thread inserts are the ideal solution for miniaturization and mechanical resistance of components.

How do you choose the right mesh insert for your application?

The choice of a net insert depends on several technical parameters:

The installation of a thread insert follows a rigorous process, including drilling, tapping and inserting. It’s essential to use the right tools to ensure optimum fastening and maximum durability.

Why choose SEDC Industrie for your net inserts?

With over 40 years’ experience in the manufacture of industrial fastening solutions, SEDC Industrie is recognized for its expertise and the quality of its products.

Contact our experts

Our team is at your disposal to help you choose and install the net inserts best suited to your needs.